Britain is known as the largest user of Eurofighter Typhoon fighter jets. In total, the Royal Air Force operates around 160 Typhoons in four tranches, making the Eurofighter Typhoon a major force in the British Empire.

Together with other NATO assets, the operational level of the British Typhoon is relatively high, and recently, it seems that "Iron Man" technology has helped to assist the readiness of the fighter jets that have been offered to Indonesia.

At Coningsby Air Base (RAF Coningsby), where BAE Systems has a contract to maintain the UK's Eurofighter Typhoon fleet, engineers and technicians are turning to futuristic technology to help keep the Typhoons in the air. The innovation that BAE Systems excels at is the use of robot suits worn by technicians.

Quoted from telegraph.co.uk (23/12/2022), the robot suit in question is an exoskeleton, which gives 'superhuman' strength to the wearer. This suit works by providing additional support to a technician's 'arm' and upper body. This means any work that is done above head level can be done easily, such as repairing parts from under a plane, and the solution reduces muscle strain.

The exoskeleton at first glance is similar to the “Iron Man” suit and is currently being tested for use on the front lines to allow ground crews to use it optimally.

BAE Systems is also testing autonomous co-bots, which are freely moving robots that can work alongside the user's exoskeleton to assist with aircraft maintenance tasks. The idea is that this cobot will handle multiple repetitive tasks that require continuity, allowing technicians to focus on tasks more efficiently.

Meanwhile, mechanical fists can be used to reduce fatigue. The glove contains five motors that strengthen the wearer's grip. While it can't bend metal bars, it can help technicians make fewer mistakes and last longer.

“This technology has helped cut the number of Eurofighter Typhoon maintenance hours required by up to 30 percent," said Chris Payne, BAE Systems Head of Future Capability for Maintenance.

Many of the above innovations are intended to reduce working time, reduce risk of injury and limit muscle strain, as well as back and knee discomfort, which force mechanics or technicians into awkward positions when turning pipes or opening panels on airplanes.

|

| Iron Man technology |

Other technologies tested for maintenance are more futuristic. For example, robots with sensitive optical sensors will be used to detect wear and tear on fuselage that is too small to be seen with the eye.

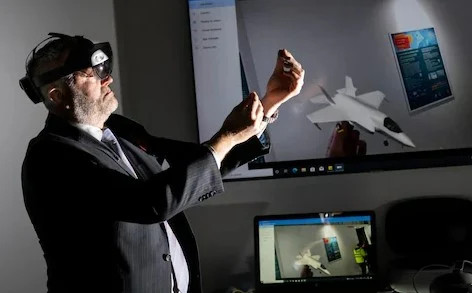

Another area the company is working on is augmented reality. Everything from videos to text documents can be loaded into an augmented reality headset, which can be displayed next to the part to be repaired or replaced. This means technicians can have hands-free access to technical documents when performing maintenance work.

Follow Daily Post on Google News to update information quickly. Thank you for visiting our website..!! Don't forget to share any information to help develop our website